One of the first things that would require some attention on this machine was that the pump plunger did not want to be removed for routine cleaning. Using some beefy channel lock pliers, we tried to pull while slowly twisting. As some books suggested, we also attempted tapping gently on the end of the plunger and then gave it another go. It wasn’t budging. However, at this point it wasn’t entirely stuck. The machine was producing slugs.

Back end of machine with view of plunger and pot. Also, notice quick drop is released

So we ignored it for the time being. The keyboard was barely functioning so I figured I’d focus on coming up with a keyboard repair plan first. I wasn’t so lucky. The next work session made it impossible for me to ignore the plunger, since it only took 5 or so more lines before the plunger became really stuck, it would no longer return to neutral position and was stuck almost at the bottom of its stroke. Fortunately, the plunger rod had popped free from the pump lever via the safety spring on the plunger rod, and the machine was not bound up. It was time to come up with a new plan for plunger extraction.

Most information that I came across regarding extracting a stuck plunger pump suggested ladling the metal out until the top of the plunger was exposed. The information then suggested to place oil or tallow in the well above the plunger and allow it to soak in for a few minutes before attempting to repeat tapping and pulling at the plunger rod with a monkey wrench. Ladling metal out of the pot at this point didn't appeal to me. I decided to explore other options before going that route.

Brian Donnell offered some additional suggestions that sounded a bit more promising:

1. Run a rod thru the upper hole and tap upwards on it with a hammer.

2. Make a loop of several strands of wire thru the top hole and use a crowbar thru the loop and against the frame.

3. Maybe don't use a wrench above the pin hole on the plunger shaft, only below the pin hole, since the rod is weak at that point.

I liked number 2. Using leverage to get at a problem seemed to be a smarter way to work rather than throwing a hammer at it. At least it seemed like a good starting point.

With option number 2 being on the top of my list, I was still hesitant to put a lot of force on this thing. Since I hadn’t done this before, I wasn’t sure what to expect. Even though I studied the illustrations in the books, what lurked beneath the molten metal was still a bit of a mystery to me.

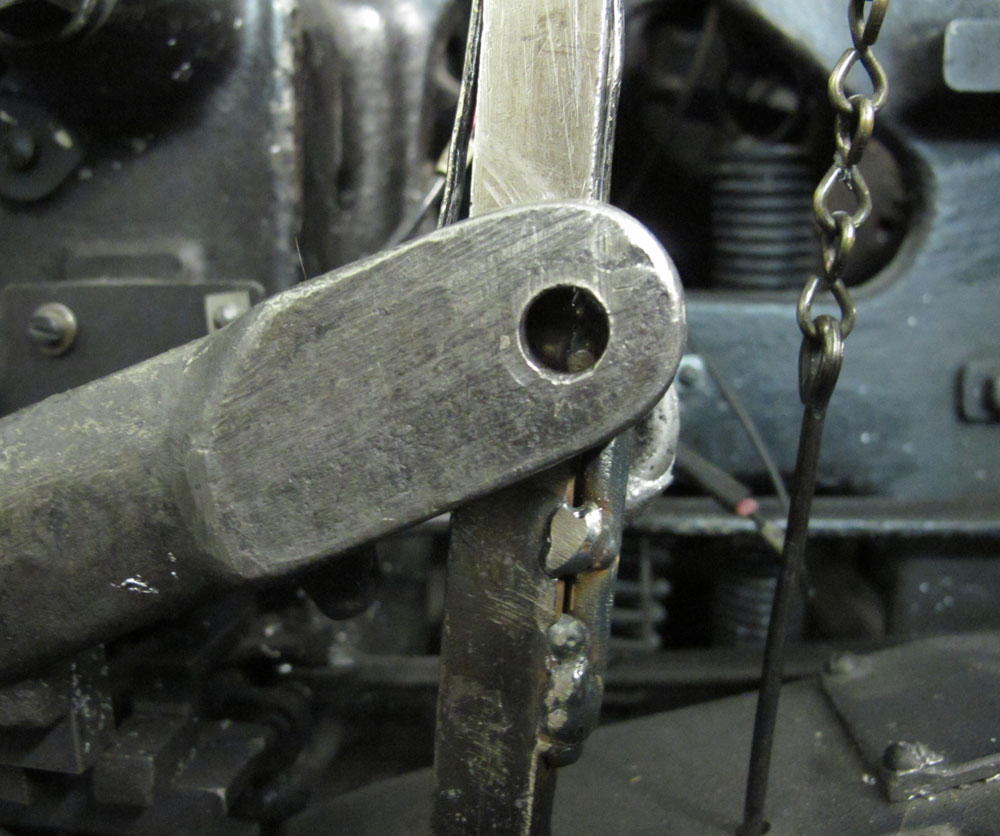

Was I going to break the rod off of the plunger? The plunger rod had a considerable amount of “slop” to it. It seemed to wiggle side to side as much as it moved with the pin front and back. Was the rod weak at this point? Had someone drilled the hole out for some reason? The exposed portion of the rod was pretty beat up, the top was tapered off from some significant hammering at some point. And as Brian’s list item 3 warned, the point at the pin hole had been severely bent and had been repaired with a chunky weld.

evidence of some rough times with the plunger

Also, another strange thing was that the plunger quick drop lever was unlatched in-spite of the knife block being set at a small point size. What’s going on here? I was imagining the worst: I’d start in with a crow bar, snap the plunger rod off and find that it was held in place by bailing wire or something.

I emailed Bill Spurling with some photos. He has dealt with plenty of machines with stuck plungers. Also, he had a number of spare plungers which he photographed and sent back to me.

A snap shot of some of Bill's spare plungers.

Looking down on plunger as it would sit in well.

Bill and these photos helped to reassure me that by torquing on the plunger rod we would not pull it off of the plunger. And if we did, well, so goes it. Bill was not intimidated. He offered to help and said that he came up with a tool for that very purpose.

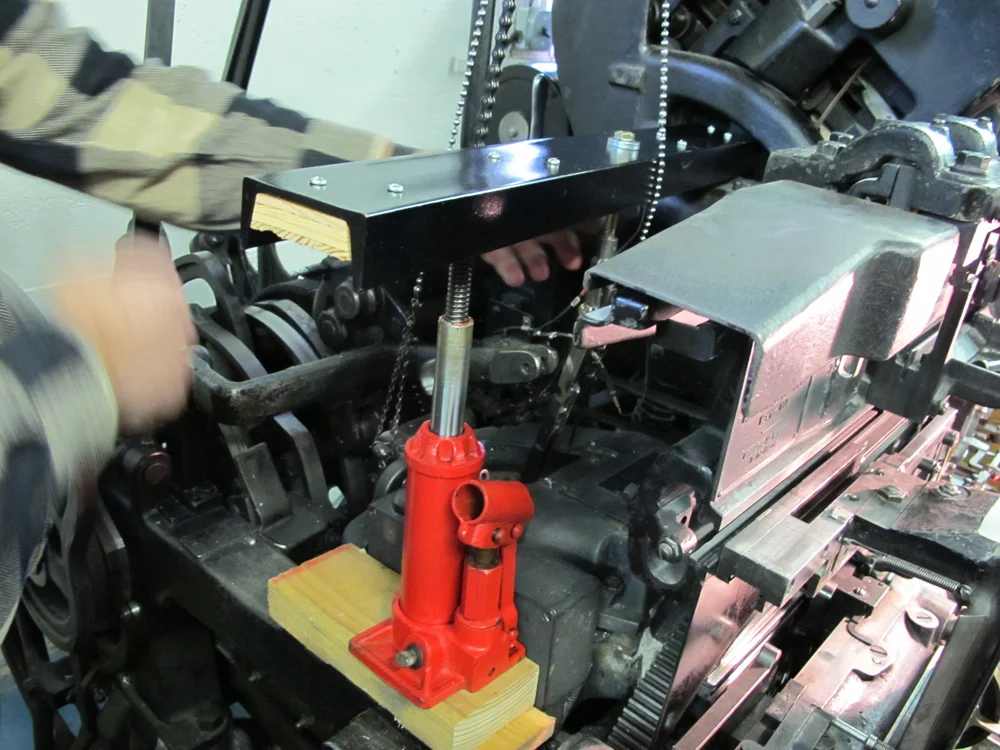

Using about $20 of materials to make, this tool will get the job done. One end rests on the main column, while the other sits on a small hydraulic jack which is positioned on the outer frame next to the pot.

We had to shim up this side a bit with wood scrap. Centered is a threaded “u-bolt” that can be adjusted to varying heights. The u-bolt is attached to the top hole of the plunger rod. When the jack is extended, the plunger is pulled with uniform upward force. It worked like a charm.

Within minutes Bill, his son Tristan and I had the plunger pulled and were practicing the routine steps of cleaning it and the well free of dross.